Elektrohebezeug

The chain electric hoist is a compact, lightweight lifting device with a rated load range of 0.25 to 5 tons, with a single chain configuration usually used below 5 tons. The recommended lifting height is 3 to 12 meters, beyond which chain failure may occur. This equipment can work with bridge cranes, gantry cranes, and jib cranes to improve material handling efficiency, and it is especially suitable for low buildings or places that require temporary expansion of lifting space, such as temporary factories.

The Weihua chain electric hoist is manufactured strictly per DIN German industrial standards; the core components, such as the chain, motor, brake, and clutch, are all imported from Germany. The reducer shell adopts an aluminum alloy die-casting process, which has both lightweight and high-strength characteristics. The appearance of the equipment is exquisite, and the internal gears are quenched at high temperatures to enhance wear resistance and impact resistance. Combined with the leading international manufacturing technology, the gear meshing precision is high, and the equipment runs stably and has a long service life.

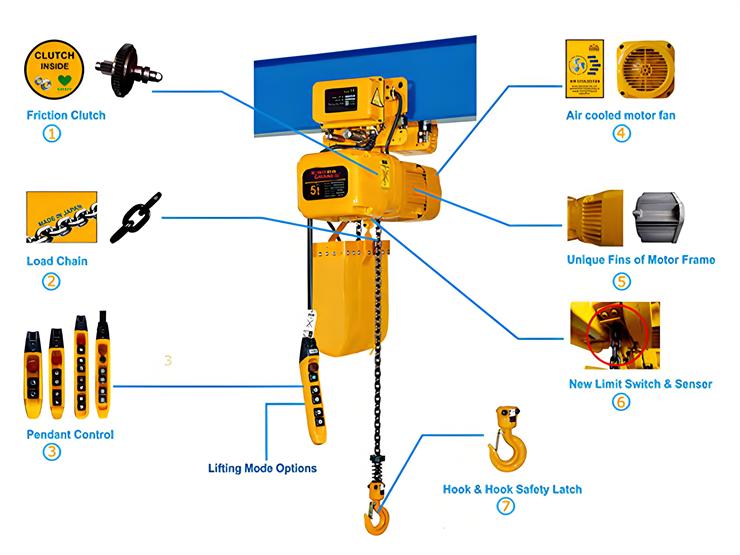

A small electric chain hoist is mainly composed of core parts such as a motor, transmission mechanism, and chain wheel. Among them, the chain and brake system are the key parts of the equipment.

Chain electric hoists are lightweight and highly efficient, widely used in manufacturing, logistics, warehousing, construction sites, maintenance, and other fields, especially suitable for limited space or need to move frequently in the operating environment. The specific applications are as follows:

| Capacity(t) | 5 | 20 | 50 | 80 |

| Hebehöhe(m) | ≤24 | ≤30 | ≤26 | ≤20 |

| Lifting Speed(m/min) | 5/0.8 | 4/0.67 | 0.53~3.2 | 0.4~2.4 |

| Travel Speed(m/min) | 2~20 | |||

| Arbeitspflicht | M5 | |||

| Stromversorgung | AC 380V 50Hz | |||

Note: Customized design according to your specific requirements.

As a famous crane and chain electric hoist manufacturer in China, Weihua always focuses on high quality and innovative technology. All electric chain hoists are CE-certified and comply with international safety standards, and we provide OEM service to meet customers' customized needs. Our products have the following advantages:

For more product details or customized services, please contact our professional team. Weihua Crane will provide you with professional technical support and solutions!

| Feature | Chain Hoist | Wire Rope Hoist |

|---|---|---|

| Lifting Medium | Uses a welded or roller load chain | Uses a multi-strand steel wire rope |

| Tragfähigkeit | Typically 0.25 to 20 tons | Typically 1 to 100+ tons |

| Hebegeschwindigkeit | Slower (1-10 ft/min) | Faster (10-60 ft/min) |

| Duty Cycle | Better for intermittent use | Designed for heavy, continuous use |

| Maintenance | Low (fewer moving parts) | Higher (requires lubrication & inspection) |

| Precision Control | Excellent (manual or electric) | Good (better for high-speed lifting) |

| Best For | Light to medium-duty, confined spaces | Heavy-duty, high-speed, long lifts |

An electric chain hoist operates using a motor-driven gear system to lift and lower loads via a durable load chain. When powered, the electric motor engages a reduction gearbox, which converts high-speed, low-torque rotation into slow, high-torque movement to turn the chain sprocket. The sprocket grips and lifts the load chain in precise increments, with a mechanical brake automatically engaging when power is cut to prevent accidental lowering.

Proper maintenance extends lifespan and ensures safe operation. We recommend following the Electric Chain Hoist Maintenance Checklist for care and maintenance.

Regular Inspection

Check for chain wear, distortion, or corrosion (replace if damaged).

Inspect hooks, latches, and load-bearing parts for cracks or deformation.

Lubrication

Apply chain lubricant regularly to reduce friction and wear.

Ensure gearbox and bearings are properly greased (follow manufacturer’s guidelines).

Electrical Components

Test switches, buttons, and control pendants for proper function.

Check wiring and connections for fraying or corrosion.

Brake & Load Test

Verify that the electromagnetic brake engages properly when power is cut.

Perform periodic load tests (at rated capacity) to ensure safety.

Cleanliness & Storage

Keep the hoist free of dust, debris, and moisture.

Store in a dry environment when not in use to prevent rust.

Sie können uns gerne eine Nachricht hinterlassen. Wir werden innerhalb von 24 Stunden antworten.

Antrag einreichen