Nachrichten

Weihua Group is a leading overhead crane factory and supplier in the world. We offer a full range of 10-ton overhead crane solutions, including single-girder overhead cranes, underhung overhead cranes, low-headroom overhead cranes, and double-girder overhead cranes. All equipment can be customized according to the customer's specific working conditions, including lifting height, span, working level, and other parameters, and additional functions. With 30 years of professional R&D and manufacturing experience, our products have been successfully exported to over 120 countries and regions worldwide, providing efficient and reliable material handling solutions to customers in various industries, including manufacturing, logistics, warehousing, iron and steel metallurgy, and others.

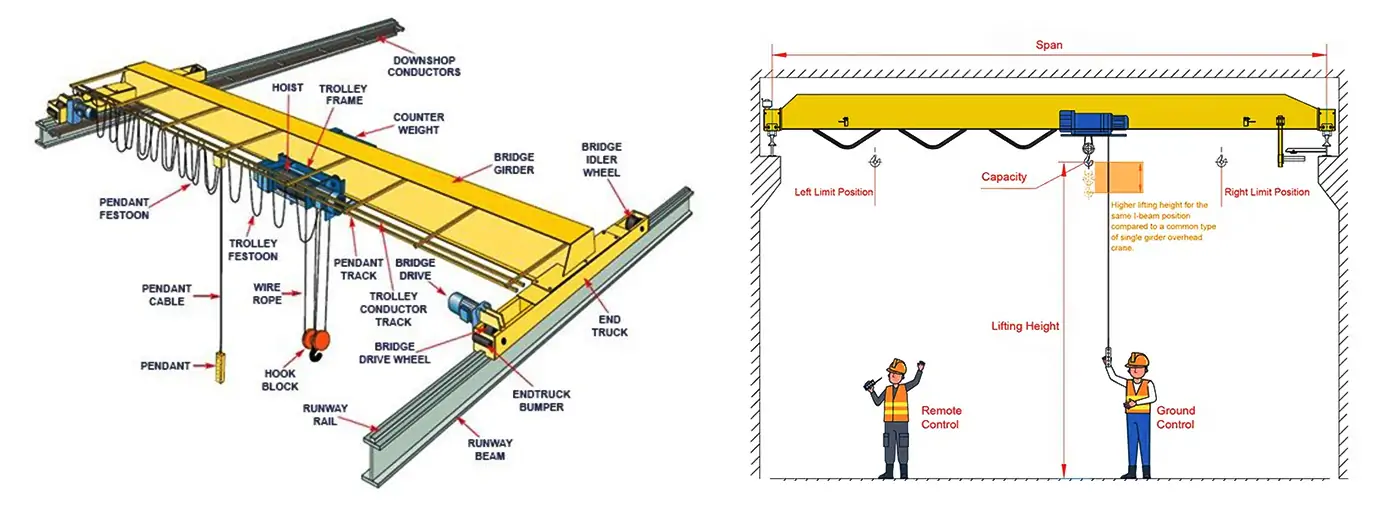

The structure of overhead cranes mainly consists of bridge frame, trolley running mechanism, lifting trolley, lifting structure and other components. The structure of overhead cranes mainly consists of bridge frame, trolley operation mechanism, lifting trolley, lifting structure, and other components. For the parts maintenance and replacement guide, please check this article: Overhead Crane Parts Maintenance and Replacement

Our 10 ton single girder overhead crane is compact in design, easy to install and operate, and is the ideal solution for medium-sized material handling in space-constrained workshops. Equipped with an electric wire rope hoist system with optional inverter control, optional radio remote control, overload protection, and automatic positioning system. It is ideally suited for light to medium duty industrial applications such as assembly lines, warehouses, and manufacturing plants. Contact us today to discuss your specific needs and obtain a customized solution package.

| Hebekraft | 1 Ton | 2 Ton | 3 Ton | 5 Ton | 10 Ton |

| Spannweite | 7.5-31.5 m | ||||

| Hebehöhe | 6m, 9m, 12 m | ||||

| Hebegeschwindigkeit | 8(8/0.8) m/min | 7(7/0.7) m/min | |||

| Fahrgeschwindigkeit des Hubwerks | 20 m/min | ||||

| Fahrgeschwindigkeit des Krans | 20(30) m/min | ||||

| Arbeiterklasse | A3, A4, A5 | ||||

| Strom | Dreistufig; 380V, 50Hz | ||||

This 10 ton overhead crane is compliant with European FEM standards and features an optimized lightweight modular design to reduce structural loads on the equipment. Typically used in conjunction with European electric hoists, it provides smooth and precise load handling through advanced variable frequency drive control. It is easy to install and low maintenance, making it an ideal solution for general manufacturing, warehouse, and light industrial applications.

| Hebekraft | 1 Ton | 2 Ton | 3 Ton | 5 Ton | 10 Ton |

|---|---|---|---|---|---|

| Hebehöhe | 6/9/12 m | 6/9/12 m | 6/9/12 m | 6/9/12 m | 6/9/12 m |

| Hebegeschwindigkeit | 5/0.8 M/min | 5/0.8 M/min | 5/0.8 M/min | 5/0.8 M/min | 5/0.8 M/min |

| Arbeiterklasse | A5 | A5 | A5 | A5 | A5 |

| Fahrgeschwindigkeit des Wagens | 2~20 M/min | 2~20 M/min | 2~20 M/min | 2~20 M/min | 2~20 M/min |

| Fahrgeschwindigkeit des Krans | 3~30 M/min | 3~30 M/min | 3~30 M/min | 3~30 M/min | 3~30 M/min |

Designed for hazardous environments, this explosion-proof overhead crane is ATEX/IECEx certified and equipped with fully enclosed motors, spark-proof components, and anti-static circuits. It is widely used in petrochemical, pharmaceutical, and grain processing facilities to safely move loads up to 10 tons. The crane is equipped with a thermal protection switch and a double brake system to ensure safe operation of the whole machine.

| Span (m) | 7.5 | 10.5 | 13.5 | 16.5 | 19.5 | 22.5 | 25.5 |

| Capacity (t) | 1~31.5 ton | ||||||

| Trolley weight (kg) | 405~740 | ||||||

| Max. Wheel load (kn) | 13.5~90.94 | ||||||

| Travel rail | P24~P43 | ||||||

| Lifting speed (m/min) | 0.8/5 | ||||||

| Lifting height (m) | 6~12m | ||||||

| Total motor power (kw) | 4.31 | 4.31 | 4.31 | 4.31 | 4.67 | 4.67 | 4.67 |

| Crane speed (m/min) | 3~30 | ||||||

| Trolley speed (m/min) | 2~20 | ||||||

| Arbeitsdienst | M5/A5 | ||||||

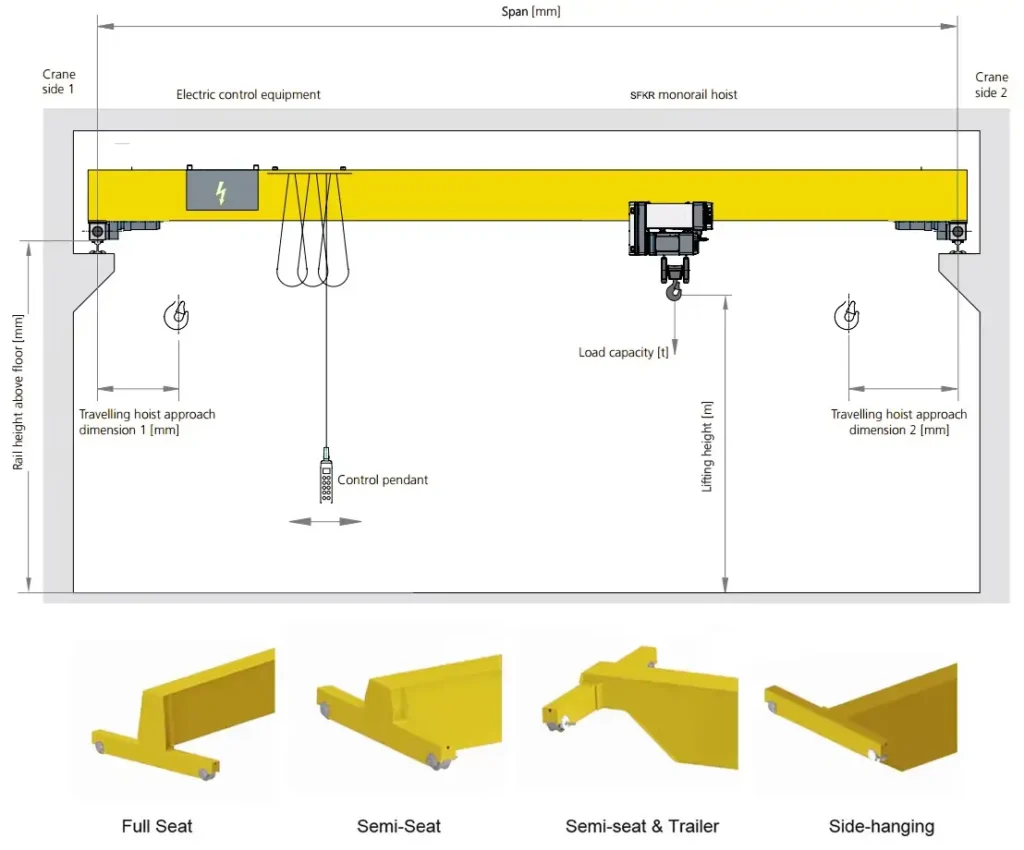

10 ton low-headroom overhead crane is a kind of lifting equipment specially designed for places with limited space height, through optimizing the structure to minimize the limiting distance from the hook to the rail surface. Adopting compact trolley and main beam integrated design, eliminating the traditional double-deck structure, so that the lifting height can be increased by more than 20% under the same plant conditions; usually equipped with low-profile electric hoists or winch mechanisms, which can operate stably under the rated load. Mainly used in machinery assembly, steel structure plants, and other working conditions that need to maximize the use of vertical space.

| Spannweite | 7.5~25.5 m | ||||||

| Kapazität | 1~32.5 ton | ||||||

| Max. Radlast | 13.5~90.94 kn | ||||||

| Travel rail | P24~P43 | ||||||

| Hebegeschwindigkeit | 0.8/5 m/min | ||||||

| Hebehöhe | 6~12m | ||||||

| Gesamtleistung des Motors | 4.31 | 4.31 | 4.31 | 4.31 | 4.67 | 4.67 | 4.67 |

| Crane speed | 3~30 | ||||||

| Trolley speed | 2~20 | ||||||

| Arbeitsdienst | M5/A5 | ||||||

A 10-ton underslung bridge crane is a type of lifting equipment that suspends the main beam directly on the supporting structure (such as a roof truss) at the top of the plant, eliminating the need for additional rail columns. It is particularly suitable for places with limited roof load or maximum ground space utilization. The headroom is very low, suitable for light steel structure plants or renovation projects.

Usually equipped with a European standard wire rope hoist or chain hoist, it runs smoothly, covers a 6-30-meter span, and meets the needs of medium-intensity material handling. It is widely used in automotive parts assembly, logistics sorting centers, food and beverage production lines, and other scenes with limited space. Optional dustproof, explosion-proof, or clean room models.

| Tragfähigkeit | 3-32T |

| Spannweite | 10.5-24M |

| Lift Height | 6-30M |

| Hebegeschwindigkeit | 8 (0.8/8)7 (0.7/7) 3.5 (0.35/3.5) 4 (0.4/4)3 (0.3/3) |

| Crba travelling speed | 20/30 m/min |

| Fahrgeschwindigkeit des Krans | 20/30 m/min |

| Arbeit Klasse | A5-A7 |

| Working Temperature | -20~40℃ |

| Stromversorgung | 3P 380V 50HZ |

| Way to Control | Pendant Push Button / Wireless Remote Controller / Cabin |

The 10 ton grab overhead crane is an efficient lifting equipment specially designed for bulk material handling, which realizes automatic grabbing, lifting, and dumping of loose materials (such as coal, ore, grain, etc.) by an integrated grab device. Equipped with electro-hydraulic or mechanical grabs, supporting double/multiple flap design, it can efficiently handle bulk materials of 0.5-10m³ capacity. Widely used in continuous operation scenarios such as coal silos in power plants, raw material storage in cement plants, bulk cargo terminals and so on. Customized dustproof, anti-corrosion, or high-temperature resistant versions are available to suit different working conditions.

| Kapazität | 2ton,3ton,5ton,10ton |

| Span(rail to rail center) | 4.5m~28.5m |

| Hebehöhe | 6m,9m,12m,18m,24m,30m |

| Hebegeschwindigkeit (m/min) | 16,14 |

| ross travelling speed(m/min) | 20,30 |

| Long travelling speed(m/min) | 20,30 |

| Dienstklasse | A3/A4 |

| Power source | 380V,50HZ,3 phase(or other standard) |

| Arbeitstemperatur | -20~40°C |

| Control model | Pendant pushbutton or remote control |

We offer fully customizable 10-ton overhead cranes to meet the specific operational needs of various industries.

Customizable parameters:

Span length: 5 m~31.5 m

Lifting height: 3 m~30 m

Working class: A3~A7 (FEM standard) / B~E class (CMAA)

Operating speed: 5~30 m/min (optional variable frequency control)

Control system: suspended/wireless remote control/fully automatic

All customized cranes are subjected to 3D load simulation during the design phase and are FEM/ISO 9001 certified. Installation supervision and operator training are optional.

As a benchmark enterprise in China's lifting equipment export, Weihua always focuses on the innovation and upgrading of crane technology, and takes the lead in integrating intelligent control systems, frequency conversion drive technology, remote monitoring, and other advanced functions into product design. Our 10-ton overhead crane series not only meets the international certification standards such as CE and ISO, but also reduces energy consumption and prolongs the service life of cranes by optimizing structural design and material selection. For detailed technical parameters or customized quotations, please feel free to contact our professional engineering team. We will provide you with one-stop service from selection consulting to installation and commissioning.

Antrag einreichen